MATS/MAPS commercial food processing systems are available exclusively through 915 Labs. The company sells both commercial production systems and a pilot-scale system for product development. All MATS systems perform both sterilization (MATS) and pasteurization (MAPS) processes. 915 Labs also offers a MAPS-only system.

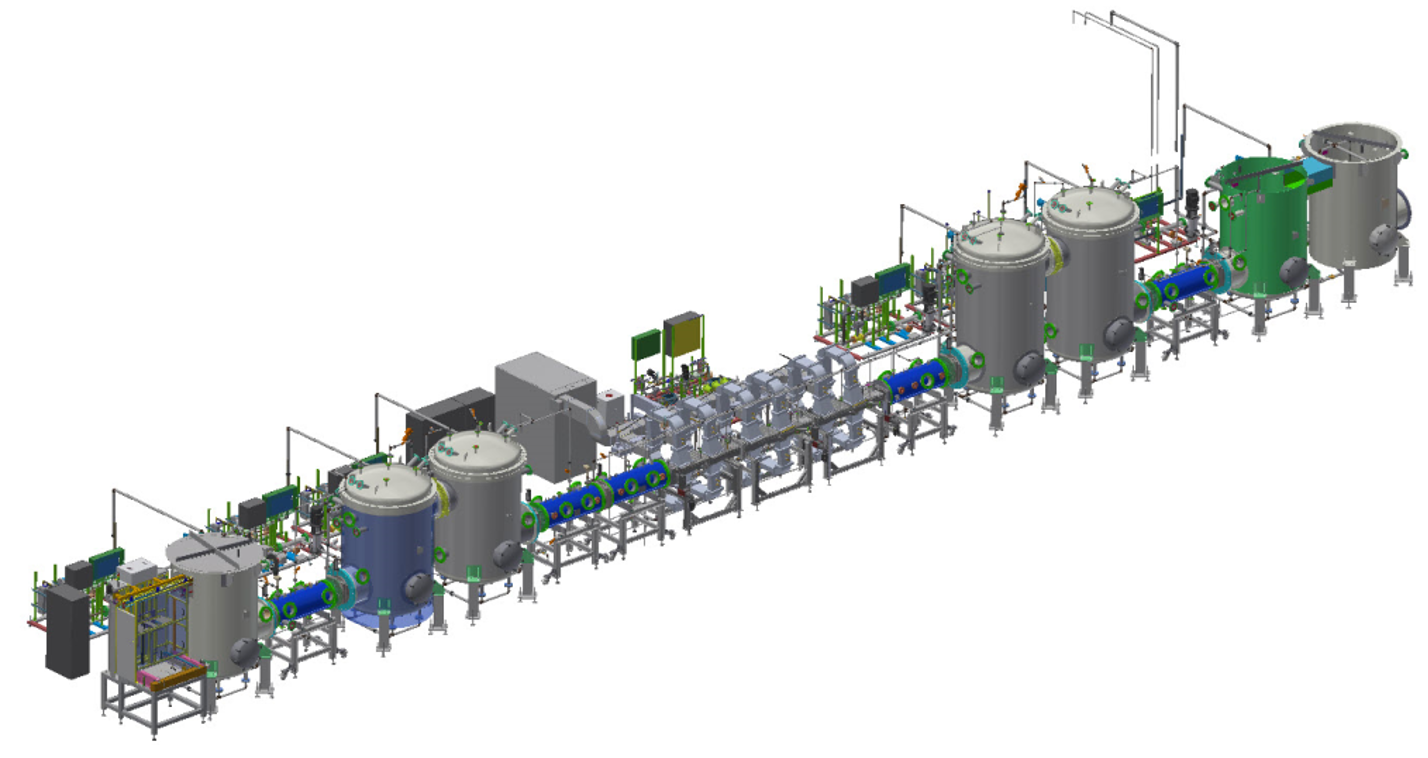

MATS-42 COMMERCIAL SYSTEM

The MATS-42 commercial production system is capable of both pasteurization and sterilization. It is designed to process up to 42 packages per minute based on a standard square tray with 8.5 ounce fill weight. Its universal carrier is configurable to a variety of packaging formats and sizes. The system is designed to integrate into modern food production facilities, making use of existing cook, fill and packaging lines.

MATS-42

MATS-B PILOT SCALE SYSTEM

The MATS-B is a pilot-scale system designed for product development labs. This system processes up to 60 packages per hour based on a standard square tray with 8.5 ounce fill weight. The universal carrier in this system is configurable to a variety of packaging formats and sizes. Chefs, culinary experts and food manufacturers work with MATS-B systems to create new packaged food recipes with fewer additives and salt. Recipes and processes developed on the MATS-B will translate directly to commercial production MATS systems.

The pilot-scale MATS-B allows food companies to:

develop recipes

produce samples for internal and market trials

validate food safety

test packaging materials and designs.

MATS-B

SYSTEMS IN DEVELOPMENT

A MATS/MAPS systems are modular and built to order, please contact us for details.

“Microwave food processing can revolutionize the quality of packaged food. The technology gives us the ability to deliver food that is much closer to fresh.”